Renault Clio: Master cylinder: Removal - Refitting

F4R or K4J or K4M or K9K or M4R, and LEFT-HAND DRIVE

WARNING

Prepare for brake fluid outflow, to prevent damage to the mechanical parts and bodywork around the braking system.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture).

- Loosen the air duct clip (1).

- Withdraw the pipe (2) on the air duct.

- Remove the air duct (3).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the electrical connector (4) from the master cylinder reservoir.

- Drain the master cylinder reservoir with a syringe.

- Remove:

- the clutch master cylinder pipe (5), if fitted to the vehicle,

- the brake pipes (6) on the master cylinder,

- the master cylinder mounting nuts (7) on the servo,

- the " master cylinder/master cylinder reservoir " assembly,

- the master cylinder reservoir mounting bolt (8) on the master cylinder,

- the master cylinder reservoir.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals (9) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the master cylinder reservoir mounting bolt on the master cylinder.

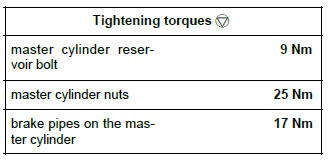

- Torque tighten the master cylinder reservoir mounting bolt (8.5 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

WARNING

When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit the nuts securing the master cylinder to the brake servo.

- Torque tighten the nuts mounting the master cylinder (25 Nm) on the servo.

- Refit the brake pipes to the master cylinder.

- Torque tighten the brake pipes on the master cylinder (17 Nm).

JH3 or JR5 or TL4

- Refit the clutch master cylinder pipe.

- Connect the electrical connector on the master cylinder reservoir.

III - FINAL OPERATION.

- Refit:

- the air duct,

- the air duct pipe.

- Tighten the air duct clip.

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

- Refit:

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

RIGHT-HAND DRIVE

WARNING

Prepare for the flow of fluid, and protect the surrounding components.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the engine cover (if fitted to the vehicle),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the connector (1) from the master cylinder reservoir.

- Drain the master cylinder reservoir with a syringe.

- Remove:

- the clutch master cylinder pipe (2), if fitted to the vehicle,

- the brake pipes (3) on the master cylinder,

- the master cylinder nuts (4) on the servo,

- the " master cylinder-reservoir " assembly,

- the master cylinder reservoir bolt (5) on the master cylinder,

- the master cylinder reservoir.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals (6) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the bolt securing the master cylinder reservoir to the master cylinder.

- Torque tighten the master cylinder reservoir bolt (9 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

- When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit the master cylinder nuts to the brake servo.

- Torque tighten the master cylinder nuts (25 Nm) on the servo.

- Refit the brake pipes to the master cylinder.

- Torque tighten the brake pipes on the master cylinder (17 Nm).

JH3 or JR5 or TL4

- Refit the clutch master cylinder pipe.

- Connect the master cylinder reservoir connector.

III - FINAL OPERATION.

- Refit:

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment).

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

D4F, and LEFT-HAND DRIVE

WARNING

Prepare for brake fluid running out, to prevent damage to the mechanical parts and bodywork around the braking system.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the electrical connector (1) from the master cylinder reservoir.

- Drain the master cylinder reservoir with a syringe.

- Remove:

- the clutch master cylinder pipe (2),

- the brake pipes (3) on the master cylinder,

- the master cylinder mounting nuts (4) on the servo,

- the " master cylinder - master cylinder reservoir " assembly,

- the master cylinder reservoir mounting bolt (5) on the master cylinder,

- the master cylinder reservoir.

REFITTING

I - REFITTING PREPARATION OPERATION

- The master cylinder seals (6) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the master cylinder reservoir mounting bolt on the master cylinder.

- Tighten to torque the master cylinder reservoir mounting bolt (8.5 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

WARNING

When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit the nuts securing the master cylinder to the brake servo.

- Tighten to torque the master cylinder mounting nuts (25 Nm) on the brake servo.

- Refit the brake pipes to the master cylinder,

- Tighten to torque the master cylinder brake pipes (17 Nm) on the master cylinder.

- Connect the electrical connector on the master cylinder reservoir.

III - FINAL OPERATION

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

M4R, and RIGHT-HAND DRIVE

WARNING

Prepare for the flow of fluid, and protect the surrounding components.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the engine cover (if fitted to the vehicle),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment).

- Disconnect the atmospheric pressure sensor connector (1).

- Remove the atmospheric pressure sensor mounting bolt (2).

- Move aside the atmospheric pressure sensor mounting.

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the connector (3) from the master cylinder reservoir.

- Drain the master cylinder reservoir with a syringe.

JH3 or JR5 or TL4

- Remove the clutch master cylinder pipe (4).

- Remove:

- the brake pipes (5) on the master cylinder,

- the master cylinder nuts (6) on the brake servo,

- the " master cylinder-reservoir " assembly,

- the master cylinder reservoir bolt (7) on the master cylinder,

- the master cylinder reservoir.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals (8) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the bolt securing the master cylinder reservoir to the master cylinder.

- Torque tighten the master cylinder reservoir bolt (9 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

WARNING

When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit the master cylinder nuts to the brake servo.

- Torque tighten the master cylinder nuts (25 Nm) on the servo.

- Refit the brake pipes to the master cylinder.

- Torque tighten the brake pipes on the master cylinder (17 Nm).

JH3 or JR5 or TL4

- Refit the clutch master cylinder pipe.

- Connect the master cylinder reservoir connector.

III - FINAL OPERATION.

- Refit the atmospheric pressure sensor mounting.

- Tighten the atmospheric pressure sensor mounting bolt.

- Connect the atmospheric pressure sensor connector.

- Refit:

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment).

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

F4R, and RIGHT-HAND DRIVE

WARNING

Prepare for the flow of fluid, and protect the surrounding components.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect:

- the fuel vapour absorber bleed solenoid valve connector (1),

- the fuel vapour absorber pipe (2) on the solenoid valve.

- Move aside the fuel vapour absorber bleed solenoid valve.

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the connector (3) from the master cylinder reservoir.

- Drain the master cylinder reservoir with a syringe.

- Remove:

- the clutch master cylinder pipe (4),

- the brake pipes (5) on the master cylinder,

- the master cylinder nuts (6) on the brake servo,

- the " master cylinder-reservoir " assembly,

- the master cylinder reservoir bolt (7) on the master cylinder,

- the master cylinder reservoir.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals (8) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the bolt securing the master cylinder reservoir to the master cylinder.

- Torque tighten the master cylinder reservoir bolt (9 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

- When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit the master cylinder nuts to the brake servo.

- Torque tighten the master cylinder nuts (25 Nm) on the servo.

- Refit the brake pipes to the master cylinder.

- Torque tighten the brake pipes on the master cylinder (17 Nm).

III - FINAL OPERATION.

- Refit the clutch master cylinder pipe.

- Connect the electrical connector on the master cylinder reservoir.

- Refit the fuel vapour absorber bleed solenoid valve.

- Connect:

- the fuel vapour absorber pipe on the solenoid valve,

- the fuel vapour absorber bleed solenoid valve connector.

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

WITHOUT ANTI-LOCK BRAKING SYSTEM

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the engine cover,

- the engine undertray,

- the air filter box air inlet pipe,

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery protective shield (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the air filter box outlet air pipe.

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Disconnect the electrical connector (1) from the master cylinder reservoir.

- Remove:

- the clutch master cylinder pipe (2),

- the brake pipes (3) from the master cylinder,

- the master cylinder nuts on the brake servo,

- the " master-cylinder and reservoir " assembly,

- the master cylinder reservoir bolt,

- the master cylinder reservoir.

WARNING

Prepare for the flow of fluid, and protect the surrounding components.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Clip the master cylinder reservoir onto the master cylinder correctly.

- Refit the bolt securing the master cylinder reservoir to the master cylinder.

- Torque tighten the master cylinder reservoir bolt (8.5 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

WARNING

When refitting the master cylinder, be sure the cup is centred in the brake servo.

- Screw the master cylinder nuts onto the brake servo.

- Torque tighten the master cylinder nuts (25 Nm) on the brake servo.

- Refit the brake pipes to the master cylinder.

- Torque tighten the brake pipes on the master cylinder (17 Nm).

III - FINAL OPERATION.

- Refit the clutch master cylinder pipe.

- Connect the electrical connector on the master cylinder reservoir.

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

- Refit:

- the air filter box outlet air pipe,

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery protective shield (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter box air inlet pipe,

- the engine undertray,

- the engine cover.

D4F, and 784, and RIGHT-HAND DRIVE

WARNING

Prepare for the flow of fluid, and protect the surrounding components.

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Disconnect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).

- Remove:

- the engine cover,

- the bolts (1) from the turbocharger heat shield,

- the turbocharger heat shield (2).

- Disconnect the upstream oxygen sensor connector at (3).

- Remove:

- the upstream oxygen sensor (4),

- the bulkhead heat shield clips (5),

- the bulkhead heat shield (6).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Drain the brake fluid reservoir with a syringe.

- Disconnect the brake fluid level sensor connector (7).

- Remove:

- the clutch master cylinder pipe (8) from the brake fluid reservoir,

- the master cylinder brake pipes (9),

- the master cylinder nuts (10),

- the "master cylinder-reservoir" assembly,

- the brake fluid reservoir bolt (11),

- the brake fluid reservoir from the master cylinder.

REFITTING

I - REFITTING PREPARATIONS OPERATION

- The master cylinder seals (12) must be replaced.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the brake fluid reservoir to the master cylinder,

- the brake fluid reservoir bolt.

- Torque tighten the brake fluid reservoir bolt (9 Nm).

- Line up the master cylinder with the brake servo so that the pushrod goes into the master cylinder housing.

- When refitting the master cylinder, be sure that the cup is centred in the brake servo.

- Refit:

- the master cylinder nuts,

- the master cylinder brake pipes,

- the cylinder pipe to the brake fluid reservoir.

- Torque tighten:

- the master cylinder nuts (25 Nm),

- the brake pipes on the master cylinder (17 Nm).

III - FINAL OPERATION.

- Refit:

- the bulkhead heat shield,

- the bulkhead heat shield clips,

- the upstream oxygen sensor.

- Torque tighten the upstream oxygen sensor (44 Nm).

- Connect the upstream oxygen sensor connector.

- Refit:

- the turbocharger heat shield,

- the heat shield bolts,

- the engine cover.

- Bleed the brake circuit (see 30A, General information, Braking circuit: Bleed, 30A-4).

- Connect the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery).