Renault Clio: Sequential gearbox: Removal - Refitting

K9K, and JA5

REMOVAL

I - REMOVAL PREPARATION OPERATION

IMPORTANT

Before any operation on the sequential system, discharge the accumulator using the Diagnostic tool.

- To discharge the accumulator, run command

" Discharge pressure accumulator " AC081.

To confirm the pressure drop, read the " Hydraulic pressure " parameter for the resulting value.

If there is still pressure in the accumulator, re-run the " Discharge pressure accumulator " command until the pressure is negligible and will not pose a risk when the high pressure pipes are removed.

The pressure reading must be close to zero.

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the air filter unit (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture).

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the engine undertray.

- Drain the sequential gearbox.

- Remove:

- the front wheels (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the front right-hand driveshaft (see 29A, Driveshafts, Front right-hand driveshaft: Removal - Refitting, 29A-9),

- the front left-hand driveshaft (see 29A, Driveshafts, Front left-hand driveshaft: Removal - Refitting, 29A-2),

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the wiring harness nut under the injection computer.

- Remove the Protection and Switching Unit bolts (1).

- Remove:

- the Protection and Switching Unit,

- the wiring harness under the injection computer.

- Fit the (Mot. 1453) with a safety strap(s).

- Remove:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the engine undertray,

- the rear suspended engine mounting (see 19D, Engine mounting, Rear suspended engine mounting: Removal-Refitting),

- the actuator module (see 21B, Sequential gearbox, Actuator module: Removal - Refitting, 21B-34),

- the pump assembly (see 21B, Sequential gearbox, Sequential gearbox: Removal - Refitting, 21B-66).

- Attach the " cooling radiator - fan unit " assembly to the upper cross member using a safety strap(s).

- Remove:

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection),

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Remove:

- the stud (2) from the actuator module on the gearbox,

- the wiring harness channel bolts on the gearbox,

- the earth wiring bolt on the gearbox.

- Disconnect the engine speed and position sensor connector.

- Remove:

- the bolt from the engine speed and position sensor,

- the engine speed and position sensor (3).

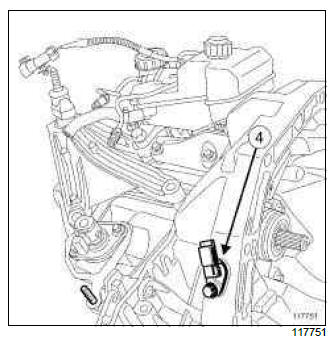

- Remove:

- the exhaust bracket bolt on the gearbox,

- the exhaust bracket nut on the gearbox,

- the exhaust bracket (4) on the gearbox,

- the starter bolts,

- the gearbox upper bolts,

- the gearbox lower bolts.

- Position the component jack (5) under the gearbox.

- Remove the gearbox.

REFITTING

I - REFITTING PREPARATION OPERATION

- Check that the engine/gearbox centring rings are in place and correctly positioned (6).

WARNING

To avoid damaging the slave cylinder, do not coat the gearbox output shaft with grease.

WARNING

To prevent leaks, replace the slave cylinder after replacing the clutch pressure plate.

Note:

- Always replace the right-hand driveshaft snap ring with a new one whenever it is removed.

- Always replace the differential output seals each time the driveshafts are removed.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the gearbox,

- the gearbox lower bolts,

- the gearbox upper bolts,

- the actuator module stud on the gearbox.

- Torque tighten the gearbox bell housing bolts (44 N.m).

III - FINAL OPERATION

- Refit:

- the starter bolts,

- the wiring channel bolts on the gearbox,

- the earth wiring bolt on the gearbox,

- the exhaust bracket bolt on the gearbox,

- the speed and position sensor,

- the exhaust bracket on the gearbox,

- the pump assembly (see 21B, Sequential gearbox, Pump assembly: Removal - Refitting, 21B-12),

- the actuator module (see 21B, Sequential gearbox, Actuator module: Removal - Refitting, 21B-34),

- the rear suspended engine mounting (see Lower engine tie-bar: Removal - Refitting) (MR 392, 19D, Engine mounting),

- Remove the (Mot. 1453) and the safety strap(s).

- Bleed the clutch circuit (see 21B, Sequential gearbox, Sequential gearbox: Bleeding, 21B-84)

- Refit:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the Protection and Switching Unit,

- the wiring harness under the injection computer,

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the air filter box (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the engine undertray,

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure),

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection).

- Fill the electro-hydraulic unit reservoir with oil (see 21B, Sequential gearbox, Sequential gearbox oil: Specifications, 21B-82) (Technical Note 6012, 04A, Lubricants) to between 32 and 38 mm above the MIN mark.

- Perform the following operations:

- the necessary programming (see Fault finding - Replacement of components (MR 394, 21B, Sequential gearbox).

WARNING

After the accumulator has been fully filled (15 seconds after the ignition has been switched on): the oil is at the MIN mark.

D4F, and JA3

REMOVAL

I - REMOVAL PREPARATION OPERATION

IMPORTANT

Before any operation on the sequential system, discharge the accumulator using the Diagnostic tool.

- To discharge the accumulator, run command

" Discharge pressure accumulator " AC081.

To confirm the pressure drop, read the " Hydraulic pressure " parameter for the resulting value.

If there is still pressure in the accumulator, re-run the " Discharge pressure accumulator " command until the pressure is negligible and will not pose a risk when the high pressure pipes are removed.

The pressure reading must be close to zero.

- Position the vehicle on a two-post lift (see Vehicle: Towing and lifting) (MR 392, 02A, Lifting equipment).

- Remove:

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the engine undertray.

- Drain the sequential gearbox.

- Remove:

- the front wheels (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the front right-hand driveshaft (see 29A, Driveshafts, Front right-hand driveshaft: Removal - Refitting, 29A-9),

- the front left-hand driveshaft (see 29A, Driveshafts, Front left-hand driveshaft: Removal - Refitting, 29A-2),

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the wiring harness nut under the injection computer.

- Remove the Protection and Switching Unit bolts (1).

- Remove:

- the Protection and Switching Unit,

- the wiring harness under the injection computer.

- Fit the (Mot. 1453) with a safety strap(s).

- Remove:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the engine undertray,

- the rear suspended engine mounting (see Lower engine tie-bar: Removal - Refitting) (MR 392, 19D, Engine mounting),

- the actuator module (see 21B, Sequential gearbox, Actuator module: Removal - Refitting, 21B-34),

- the pump assembly (see 21B, Sequential gearbox, Pump assembly: Removal - Refitting, 21B-12).

- Attach the " cooling radiator - fan unit " assembly to the upper cross member using a safety strap(s).

- Remove:

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection),

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure).

II - OPERATION FOR REMOVAL OF PART CONCERNED

- Remove the stud (2) from the actuator module on the gearbox.

- Lift the cooling hose (3) to access the wiring harness channel bolts on the gearbox.

- Remove:

- the wiring harness channel bolts on the gearbox,

- the earth wiring bolt on the gearbox

- Disconnect the engine speed and position sensor connector.

- Remove:

- the bolt from the engine speed and position sensor,

- the engine speed and position sensor (4).

- Remove:

- the flywheel protector bolt (6),

- the flywheel protector (5),

- the starter bolts,

- the gearbox upper bolts,

- the gearbox lower bolts.

- Position the component jack (7) under the gearbox.

- Remove the gearbox.

REFITTING

I - REFITTING PREPARATION OPERATION

- Check that the engine/gearbox centring rings are in place and correctly positioned (8).

WARNING

To avoid damaging the slave cylinder, do not coat the gearbox output shaft with grease.

WARNING

To prevent leaks, replace the slave cylinder after replacing the clutch pressure plate.

Note:

- Always replace the right-hand driveshaft snap ring with a new one whenever it is removed.

- Always replace the differential output seals each time the driveshafts are removed.

- Always replace the hydraulic clutch thrust bearing.

II - REFITTING OPERATION FOR PART CONCERNED

- Refit:

- the gearbox,

- the gearbox lower bolts,

- the gearbox upper bolts,

- the actuator module stud on the gearbox.

III - FINAL OPERATION

- Refit:

- the starter bolts,

- the wiring channel bolts on the gearbox,

- the earth wiring bolt on the gearbox,

- the flywheel protector,

- the speed and position sensor,

- the pump assembly (see 21B, Sequential gearbox, Pump assembly: Removal - Refitting, 21B-12),

- the actuator module (see 21B, Sequential gearbox, Actuator module: Removal - Refitting, 21B-34),

- the rear suspended engine mounting (see Lower engine tie-bar: Removal - Refitting) (MR 392, 19D, Engine mounting),

- Remove the (Mot. 1453) and the safety strap(s).

- Bleed the clutch circuit (see 21B, Sequential gearbox, Sequential gearbox: Bleeding, 21B-84)

- Refit:

- the side stiffener bolts on the left-hand side of the vehicle,

- the side stiffener on the left-hand side of the vehicle,

- the front left-hand wheel arch liner (see Front wheel arch liner: Removal - Refitting) (MR 393, 55A, Exterior protection).

- the Protection and Switching Unit,

- the wiring harness under the injection computer,

- the diesel injection computer (see Diesel injection computer: Removal - Refitting) (MR 392, 13B, Diesel injection),

- the scoop under the scuttle panel grille (see Scoop under the scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the scuttle panel grille (see Scuttle panel grille: Removal - Refitting) (MR 393, 56A, Exterior equipment),

- the air filter box (see Air filter unit: Removal - Refitting) (MR 392, 12A, Fuel mixture),

- the battery tray (see Battery tray: Removal - Refitting) (MR 392, 80A, Battery),

- the battery (see Battery: Removal - Refitting) (MR 392, 80A, Battery),

- the front left-hand wheel (see Wheel: Removal - Refitting) (MR 392, 35A, Wheels and tyres),

- the engine undertray,

- the radiator mounting cross member (see Radiator mounting cross member: Removal - Refitting) (MR 393, 41A, Front lower structure),

- the front bumper (see Front bumper: Removal - Refitting) (MR 393, 55A, Exterior protection).

- Fill the electro-hydraulic unit reservoir with oil (see 21B, Sequential gearbox, Sequential gearbox oil: Specifications, 21B-82) (Technical Note 6012, 04A, Lubricants) to between 32 and 38 mm above the MIN mark.

- Perform the following operations:

- the necessary programming (see Fault finding - Replacement of components (MR 394, 21B, Sequential gearbox).

WARNING

After the accumulator has been fully filled (15 seconds after the ignition has been switched on): the oil is at the MIN mark.